- Item

- 1969-10-16

Part of Richards Studio Photographs

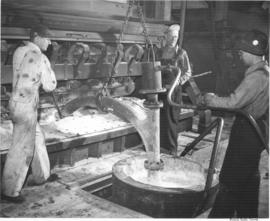

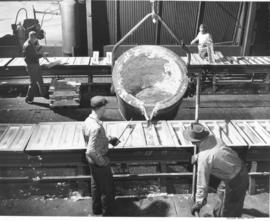

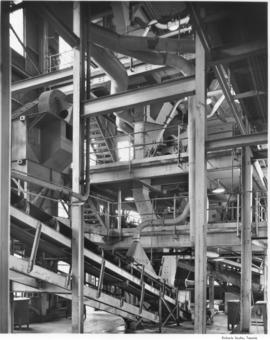

Molten liquid is being poured into molds at Fick Foundry, 1005 East D Street, in October of 1969. In business since 1924, Fick Foundry were producers of "quality static and centrifugal castings in most ferrous metals, and close tolerance aluminum centrifugal castings." The company had suffered through three major fires and was rebuilt each time. It would finally close in the late 1980's. Photograph ordered by Winston Fournier & Associates, Dallas.

Fick Foundry Co. (Tacoma); Foundries--Tacoma--1960-1970; Founding--Tacoma--1960-1970; Hoisting machinery;