- Item

- 1948-01-29

Part of Richards Studio Photographs

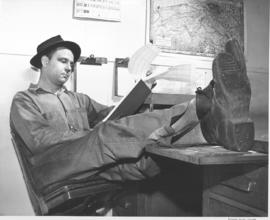

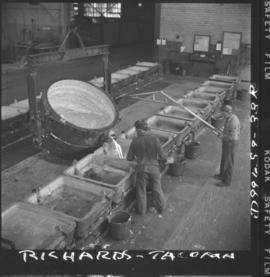

Permanente. An employee of Permanente at the Tacoma plant looks very grateful for the medical assistance received from a nurse in the medical unit. He is now wearing a large, gauze bandage on his thumb. In 1947-1948 Permanente reported having nearly 5,000 employees in their several locations in Baton Rouge, Louisiana; Owens Lake, Natividad, Oakland, and Moss Landing, California; and Mead, Trentwood and Tacoma, Washington. (Permanente Metals Corporation Annual Report 1947-1948)

Permanente Metals Corp. (Tacoma)--Employees; Aluminum industry--Tacoma--1940-1950; Infirmaries--Tacoma--1940-1950; Nurses--Tacoma--1940-1950; Wounds & injuries--Tacoma; Accidents--Tacoma;