- Item

- 1949-08-08

Part of Richards Studio Photographs

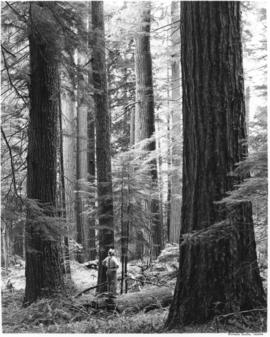

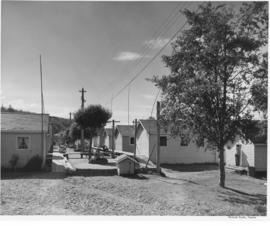

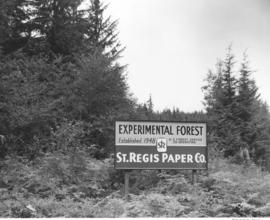

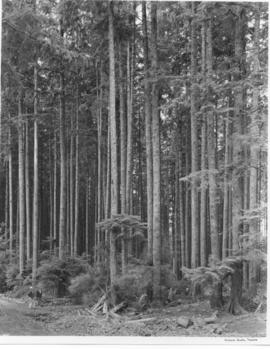

St. Regis' expansion project started after World War II ended in 1945, the company was able to begin paper production in Tacoma in January 1949. View of the St. Regis Paper Company's crew at Camp #2, located in Mineral, Washington; unidentified laborer is surrounded by huge firs.

Woodcutters--1940-1950; Loggers--Mineral--1940-1950; Paper industry--Tacoma--1940-1950; Lumber industry--Tacoma--1940-1950; Logs; Firs; Forests--Mineral; Cutover lands--Mineral--1940-1950; Woodcutting--Mineral; St. Regis Paper Co. (Mineral);