- Item

- 1952-04-15

Part of Richards Studio Photographs

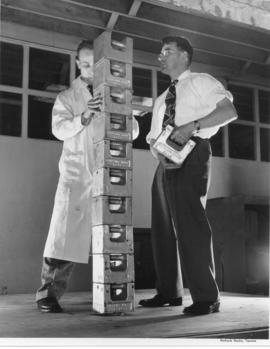

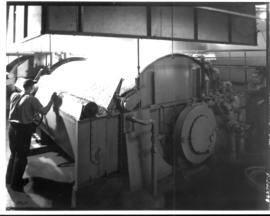

Exposure of "concentrated load test" at DFPA lab. Scientists measure results as several 50 pound weights, totaling 500 lb., are place on top of a circle of plywood. Random testing of the plywood produced in all mills provided quality control. Two laboratories, one in Tacoma and another in Eugene, conducted a continuing program of testing and research funded and supported by the industry itself.

Plywood industry--Tacoma--1950-1960; Testing; Experiments; Douglas Fir Plywood Association (Tacoma);