- Item

- 1953-09

Part of Richards Studio Photographs

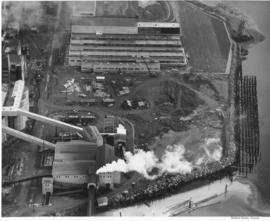

Hooker Electrochemical Company. Railroad barge owned by Griffco and tug "Mogul" moored side by side at wharf. Barge loaded with Hooker chemical tanks. Railroad yard in background.

Chemical industry--Tacoma--1950-1960; Hooker Electrochemical Co. (Tacoma); Barges; Shipping--Tacoma--1950-1960;