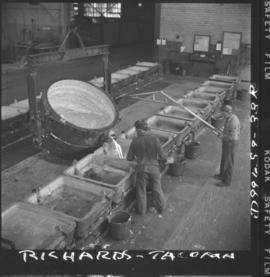

- Item

- 1948-04-27

Part of Richards Studio Photographs

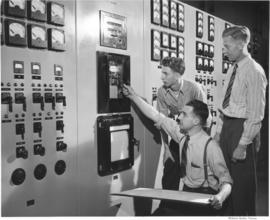

Publicity shots at Permanente Metals, Bill Gorman. Two of the staff at Permanente are checking the pressure through a hose and narrow pipe on the arm of the young man in a chemical lab. Glass containers and tubing are set up on the counter in front of them. They both wear aprons with bibs. The woman has her goggles lifted up onto her forehead. TPL-4555

Permanente Metals Corp. (Tacoma)--Employees; Aluminum industry--Tacoma--1940-1950; Employees--Tacoma--1940-1950; Laboratories--Tacoma--1940-1950;