- Item

- 1949-05-16

Part of Richards Studio Photographs

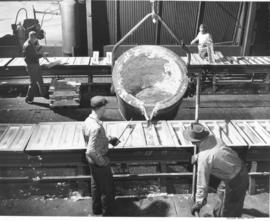

Crust breaking machine at Permanente, Bill Gorman. A specialized machine has been manufactured to perform the work that had previously been done manually. A crust would form at the openings to the reduction pots where alumina was melted into raw pig aluminum. The plant had two potlines containing 240 reduction pots producing 41 million pounds of alumium per year. (Permanente Metals Corp. 1947-1948 Annual Report)

Permanente Metals Corp. (Tacoma); Aluminum industry--Tacoma--1940-1950; Machinery;