- Item

- 1936-12-21

Part of Marvin Boland Photographs

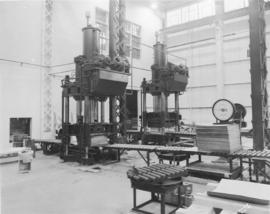

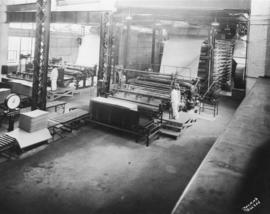

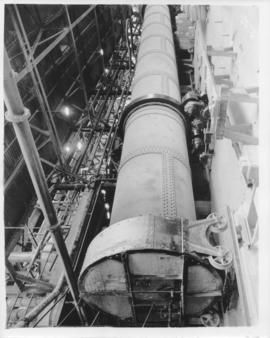

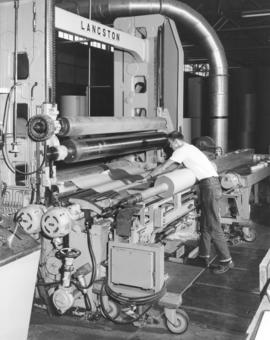

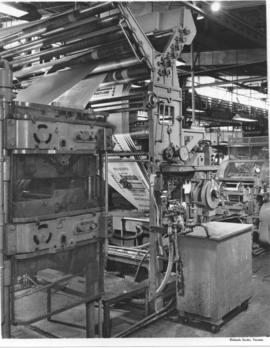

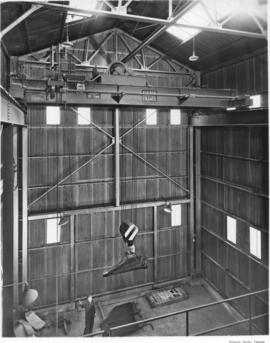

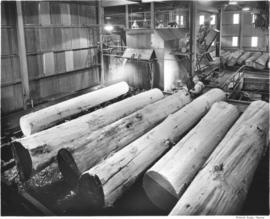

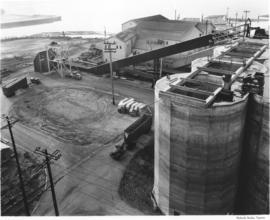

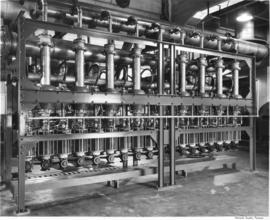

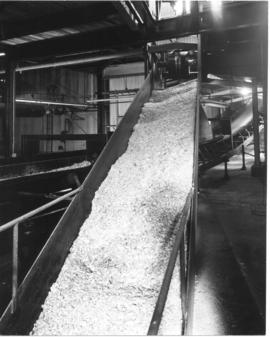

1936 daily operations at St. Regis. In late 1936 St. Regis Kraft Co.'s Tacoma plant began operating with a crew of 250 at its newly remodeled and modernized facility in the Tideflats. Boland studios paid visits to the pulp plant on December 21-22, 1936, to photograph the new interiors including machinery. Here two unidentified St. Regis employees focus their attention of one of the new machines. G37.1-048 (T.Times 10-14-36, p. 5-article; T. Times 11-25-36, p. 5-article)

St. Regis Paper Co. (Tacoma)--1930-1940; Paper industry--1930-1940; Lumber industry--1930-1940; Mills--Tacoma--1930-1940; Machinery;