- Item

- 1953-07-22

Part of Richards Studio Photographs

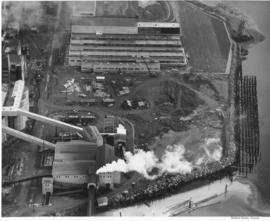

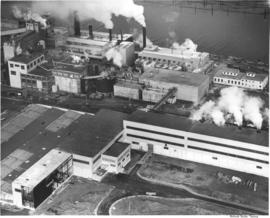

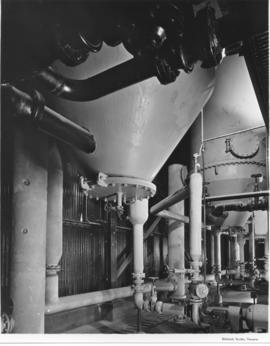

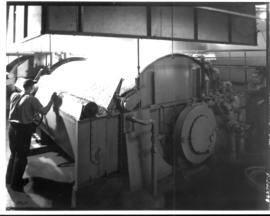

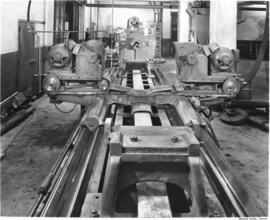

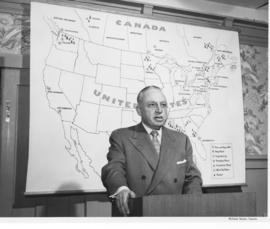

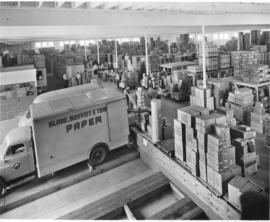

New improvements in technology are responsible for kraft and board machines that can operate at speeds up to 1500 feet per minute and can produce a sheet that can be trimmed to 212 inches in width. These high production machines helped St. Regis Paper Co. to increase total tonnage of kraft paper and boards, thereby solidifying its position as a dependable long-term source of these products to industry customers. View of interior of Florida St. Regis plant, either in Jacksonville or Pensacola. Photograph ordered by Beloit Iron Works, Beloit, Wisconsin. (1955 St. Regis Annual Report, p. 15)

St. Regis Paper Co.; Paper industry; Machinery; Beloit Iron Works (Beloit, WI);