- Item

- 1943-01-10

Part of Richards Studio Photographs

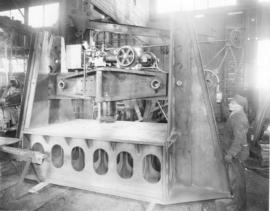

Pacific Iron & Steel Works, 1602 Canal St.(now Portland Ave.) The worker appears tiny next to a large piece of machinery in the foundry and the steel manufactured piece that he is working on.

Pacific Iron & Steel Works (Tacoma); Foundries--Tacoma--1940-1950; Steel industry--Tacoma-- 1940-1950;