- Item

- 1956-02-14

Part of Richards Studio Photographs

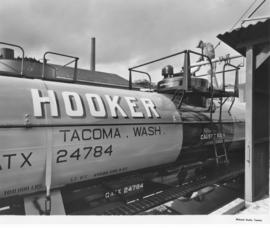

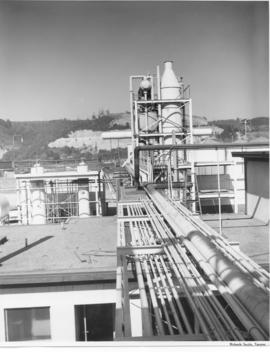

Reichhold Chemicals was constructing a new plant in the Tideflats in early 1956. It was a national company, based in White Plains, New York. A group of five railway employees stand in front of the Tacoma Belt Line #905 engine and boxcars. Reichhold would have rail transport directly from its plant, facilitating delivery of its products. Photograph ordered by Reichhold Chemicals, Inc.

Reichhold Chemicals, Inc. (Tacoma); Railroad locomotives--Tacoma--1950-1960; Railroad freight cars--Tacoma--1950-1960;