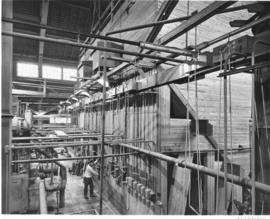

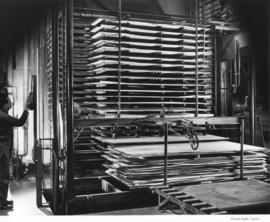

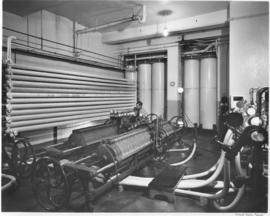

In December of 1950, an unidentified worker was photographed on the floor of the Tacoma Vegetable Oils, Inc., half-million dollar copra processing plant. The plant had recently opened on the McCormick Dock at 535 Dock Street. Copra is dried coconut meat that yields coconut oil. The plant digested the copra and extracted the oil. The oil would go to manufacturers in Chicago, Cincinnati, Boston and other eastern cities. The remaining meal was used locally for cattle feed. The plant was able to process 100 tons of copra a day with three machines. E.L. Westenhaver was vice-president and manager of Tacoma Vegetable Oils, Inc., which closed in the mid-1960s. Ordered by Westinghouse Electric Supply, Verne Hoggers. (TNT, 3/19/1950, p.A-9)

Tacoma Vegetable Oils, Inc. (Tacoma); Factories--Tacoma--1950-1960;