- Item

- 1971

Part of Richards Studio Photographs

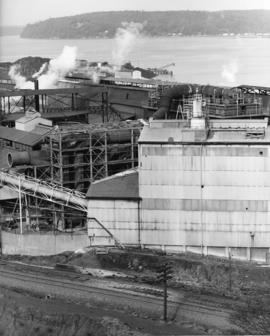

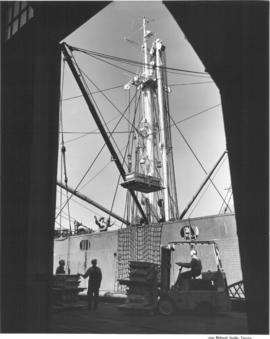

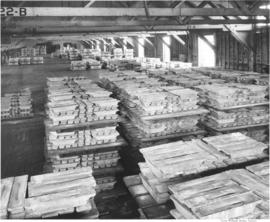

ca. 1971. Crane operations - customer negatives. Planks placed on a tilted board may have come from the boxcar nearby. Photographs requested by Star Iron & Steel Co., major crane manufacturer. Crane units visible were under construction by Star Iron & Steel; cranes, hoists and special machinery made up 70% of the company's annual volume. The company also specialized in fabricated steel and aluminum. See D159837, image 13, for progress photograph of crane. (TNT 12-13-70, C-21 - article)

Star Iron & Steel Co. (Tacoma); Hoisting machinery; Railroad freight cars--Tacoma--1970-1980;