- Item

- 1952-09-25

Part of Richards Studio Photographs

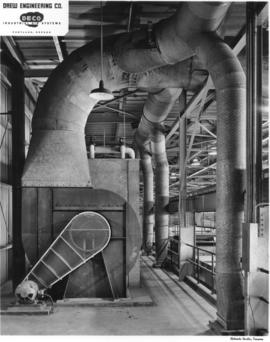

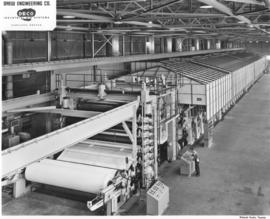

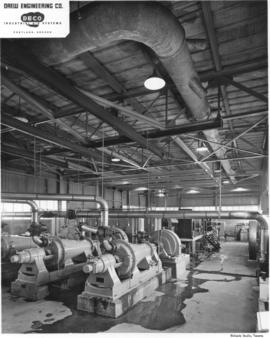

The interior Weyerhaeuser's bleached Kraft mill at Longview, Washington, showing large conduit and a fan, part of the air system in the plant. Ordered by Drew Engineering Company, Portland, Oregon, manufacturers of industrial air systems.

Weyerhaeuser Timber Co. (Longview); Mills--Longview; Lumber industry--Longview; Drew Engineering Co. (Portland); Machinery; Fans (Machinery);