- Item

- 1955-03-03

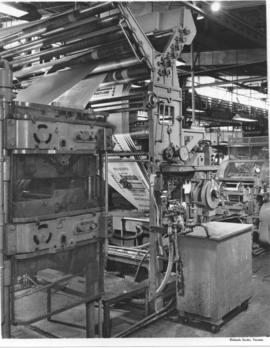

Part of Richards Studio Photographs

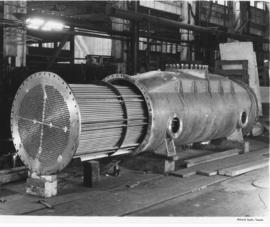

Birchfield Boiler; heat exchanger and casing. This huge condenser is one of a pair manufactured by Birchfield Boiler for the St. Regis Paper and Pulp plant. The condenser is used to recover waste heat from pulp digesters. Because they come in contact with corrosive substances, the tubes are stainless steel. There are 1184 of them, more than 3 1/2 miles of tubing in each unit. The shells and ends are made of 1 1/2 inch steel plate. Each condenser was valued at $25,000. (TNT 3/13/1955, pg. B-17)

Birchfield Boiler, Inc. (Tacoma); Boilers; Boiler industry--Tacoma; Paper industry--Tacoma--1950-1960;