- Item

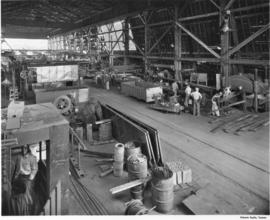

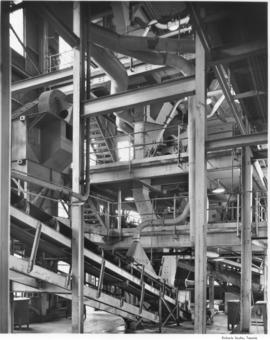

- 1953-07-02

Part of Richards Studio Photographs

Aerial view of American Smelting & Refining Co.'s (ASARCO) smokestack, smelter plant and surrounding area. ASARCO occupied a large area near Point Defiance and contributed greatly to Tacoma's economy in the fifties. As we know now, the by products of the smelting process were highly toxic, and qualified this area as a Superfund clean up area. TPL-9290

American Smelting & Refining Co. (Tacoma); Smelters--Tacoma--1950-1960; Copper industry--Tacoma--1950-1960;