- Item

- 1956-09-09

Part of Richards Studio Photographs

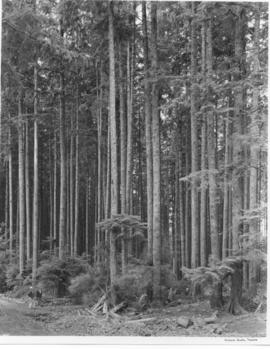

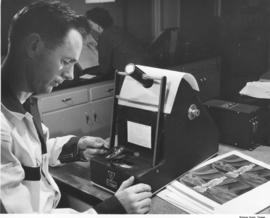

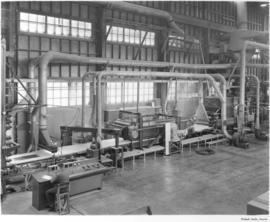

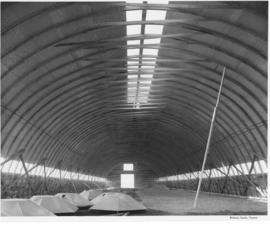

Rayonier and Rayflo plants, ordered by Malcolm McGhie. Rayonier, Inc. manufactured paper, pulp, cellulose products and wood chips. This series of pictures appears to have been taken at the Port Alice, British Columbia, cellulose mill and woodmill. Port Alice was part of Alaska Pine, the Canadian subsidiary of Rayonier, Inc. The logs in the photograph appear to be undergoing the "barking" process. The bark is removed from the log and and the remaining product will either be processed for cellulose pulp or wood chips.

Lumber industry--British Columbia--1950-1960; Trees; Logs; Alaska Pine & Cellulose Limited (Port Alice B.C.);