- Item

- 1954-03-22

Part of Richards Studio Photographs

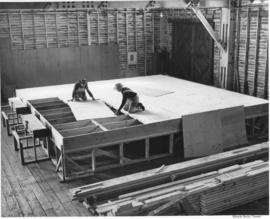

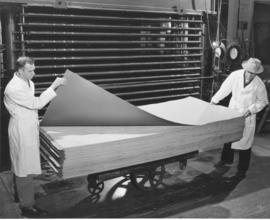

Workers are laying plywood in apparent preparation for testing by the Douglas Fir Plywood Association's laboratory in March, 1954. Nearly all sections of plywood have been fastened with only a few sheets left to attach. Plywood was constantly being tested to assure consumers and the industry that all standards were being met.

Plywood; Douglas Fir Plywood Association (Tacoma); Testing--Tacoma; Product inspection--Tacoma;