- Item

- 1956-06-27

Part of Richards Studio Photographs

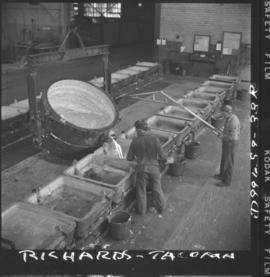

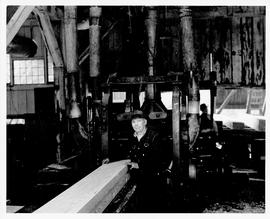

Pulp manufacturing machinery at R.W. Paper Co. in Longview, Wa. Photograph ordered by Malcolm McGhie. Workers handle large rolls of finished pulp. Once dried in the drying machine, the sheet of pulp passes between immense rolls of heated steel called calenders. These cylinders compress and smooth the surface of the sheet. As the product is rolled, it is inspected for water content, smoothness, weight, color, resistance and opacity.

R. W. Paper Co. (Longview); Paper industry--Longview--1950-1960;