- Item

- 1950-12-18

Part of Richards Studio Photographs

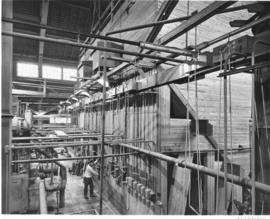

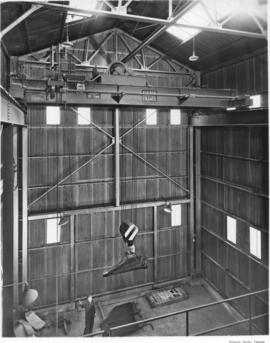

Galvanizing operations at the Bethlehem Pacific Coast Steel Corporation facilities in Seattle where iron or steel was coated with molten zinc to produce a coating of zinc-iron alloy. Long, narrow heated vats stand along the factory floor. A workman operates an overhead crane for lowering and lifting materials being galvanized. The crane can move horizontally along overhead rails. The company listed a Rolling Mill at 4001 28th Ave. S.W.; Bolt & Nut Dept. at 3800 Iowa Ave.; Tank Farm at 3301 26th Ave. S.W.; and a Mill Depot at 3845 26th Ave. S.W. Ordered by Bethlehem Steel, Bill Briscoe.

Factories--Seattle; Steel industry--Seattle; Hoisting machinery; Bethlehem Pacific Coast Steel Corp. (Seattle);