- Item

Part of Richards Studio Photographs

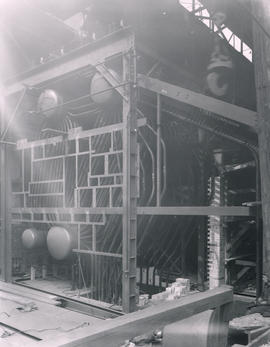

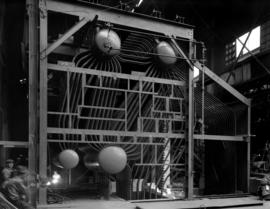

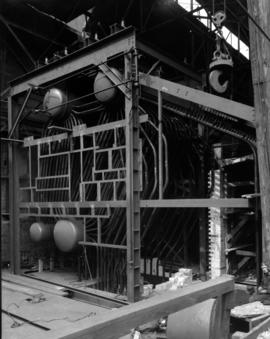

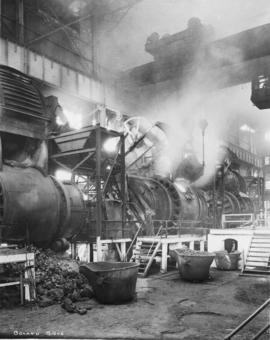

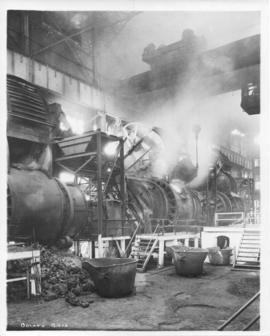

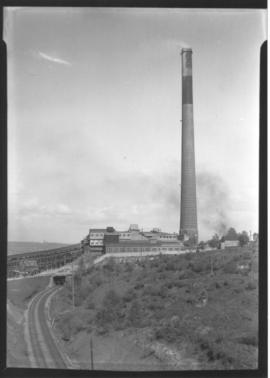

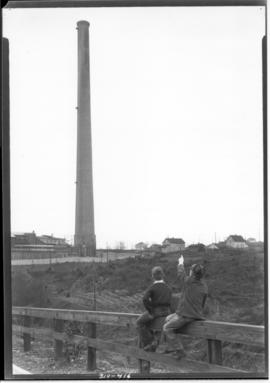

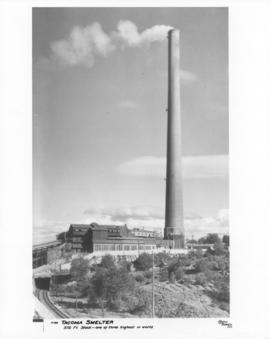

The American Smelting & Refining Co. (ASARCO Incorporated) Tacoma Plant. TPL-2353. Areas of the plant are labelled with arrows and typed notations. Typed notations read, left hand side, top to bottom: Main Stack, Silos, ESP'S (Hoppers), Flue, Metallic Arsenic Area, Arsenic Kitchens, Arsenic Roasters (Hoppers, Roaster Baghouse Hoppers, Herreshoff Roasters), Acid Plant Bldg (Settling Tanks & Basin), Fine Ore Storage (Settling, evaporation and neutralization impoundment Waste Piles), Liquid SO2 Plant. Across the top, left to right: Laboratory Container Storage, Reverberatory Furnaces, Oil Tanks, Refineries, Settling & Evaporation Basins. Right hand side, top to bottom: Slag Dump, Casting Furnace, Anode Furnaces, Nickel Plant, Converters, Unloading Dock, Crushing & Sampling Mill, Incinerator, and Ore Piles. TPL-2353, TPL-6246

American Smelting & Refining Co. (Tacoma); Smelters--Tacoma--1950-1960; Copper industry--Tacoma--1950-1960;