- Item

- 1949-09-23

Part of Richards Studio Photographs

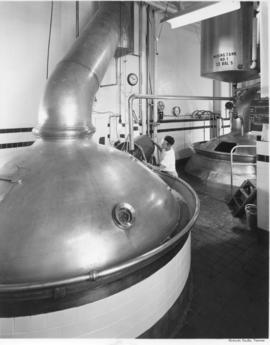

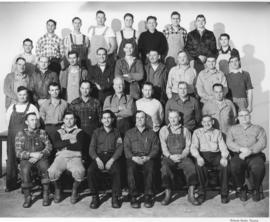

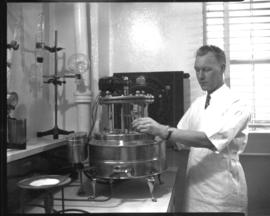

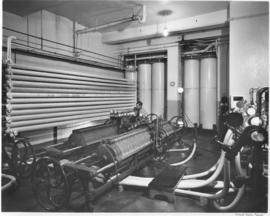

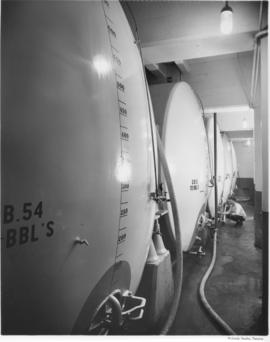

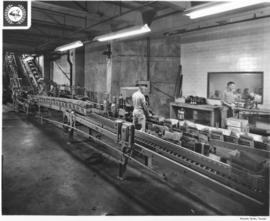

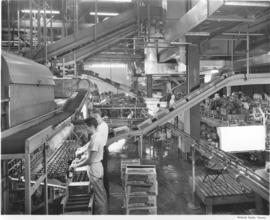

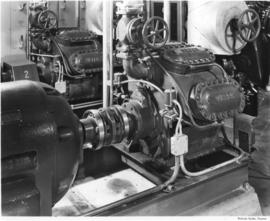

Columbia Breweries, manufacturers of Alt Heidelberg and Columbia Ale, expanded and modernized their brewing facilities and offices once again starting in 1949. This view shows the Tacoma plant and railroad siding that allowed freight trains easy access for shipping Columbia Brewery products. Packaged beer was conveyed from the bottle shop to the shipping depot through an elevated bridge which crossed the railroad yards. (TNT, 1/8/1952, p.B-7)

Brewing industry--Tacoma--1940-1950; Railroad freight cars--Tacoma; Industrial facilities--Tacoma; Columbia Breweries, Inc. (Tacoma)--1940-1950;