- Item

- 1944-06-20

Part of Richards Studio Photographs

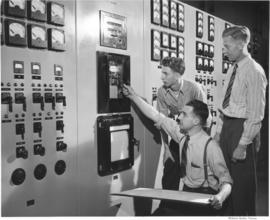

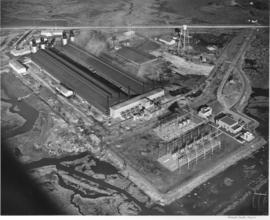

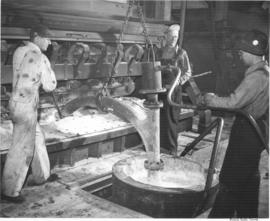

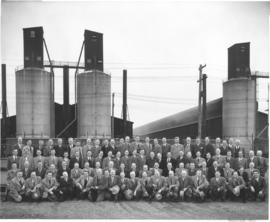

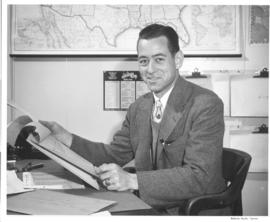

Leo Olsen lost the use of his legs to infantile paralysis when he was 9 years old, but he was determined to be part of WWII. Although a tailor by trade, and a pianist, he found work at the Olin Coporation aluminum plant, on the tide flats, running one of the giant cranes that towered over the electric furnaces. This photograph of Mr. Olsen at the controls of his crane was taken in June of 1944 for the Tacoma Chamber of Commerce. (T. Times, 6/27/44, p. 2). Tacoma Chamber of Commerce Manpower publicity at Olin Corp.

Aluminum industry--Tacoma--1940-1950; Handicapped persons--Tacoma; Olin Industries, Inc. (Tacoma); Olsen, Leo;