- Item

- 1956

Part of Richards Studio Photographs

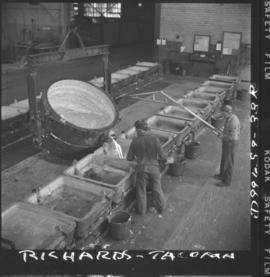

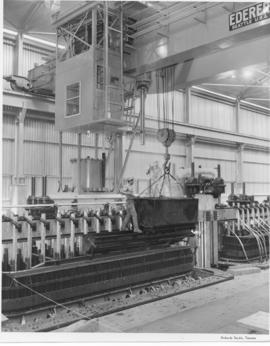

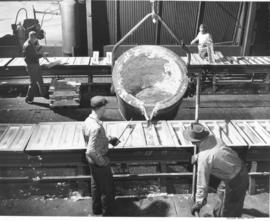

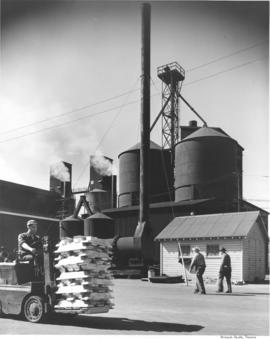

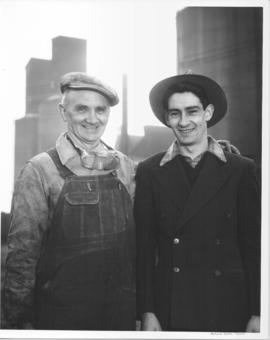

ca. 1956. Kaiser Aluminum plant. The Tacoma plant was a reduction plant, where treated ore (alumina) was subjected to an electrical current, dividing the oxygen from the pure metal (aluminum.) The plant employed approximately 500 workers, who worked on a 24 hour, around the clock basis. Its payroll was over $2,000,000 a year, and it purchased more than $1,300,000 of Northwest materials, supplies and services in a year. It was part of the Kaiser Industries conglomerate founded by Henry J. Kaiser, a diverse group of businesses that included paving, dam construction, ship building, the production of aluminum, steel, cement and other building materials, automobile production and Kaiser foundation heath care. (Kaiser Aluminum News, August 1956 and "The Kaiser Story")

Kaiser Aluminum & Chemical Corp. (Tacoma); Aluminum industry--Tacoma--1950-1960;