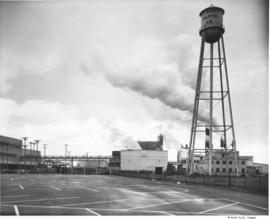

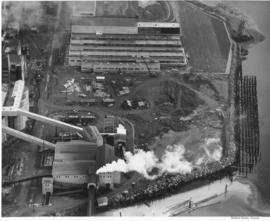

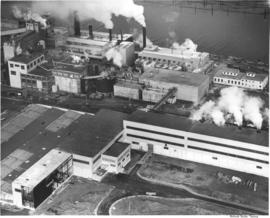

Construction continues on new buildings at the St. Regis Paper Company on Portland Avenue. Still in its early stages in August, 1951, the new buildings have been mapped out with low walls but as the mounds of dirt indicate, no flooring is in place. St. Regis was nearing completion of its eight year expansion plan; this structure is probably the multiwall bag plant which was completed in 1952. Anticipated to add an additional 400 workers to the St. Regis payroll, the new plant, constructed of steel and concrete, would be used for the production of industrial-use bags for cement, fertilizer, and other heavy-duty items. Hooker Electrochemical's tank cars can be seen in the background close to the St. Regis water tower.

Progress photographs; St. Regis Paper Co. (Tacoma)--1950-1960; Paper industry--Tacoma--1950-1960; Factories--Tacoma--1950-1960;