- Item

- 1949-02-09

Part of Richards Studio Photographs

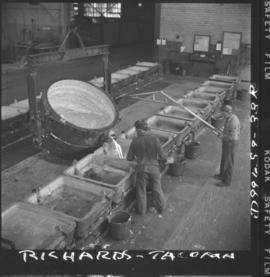

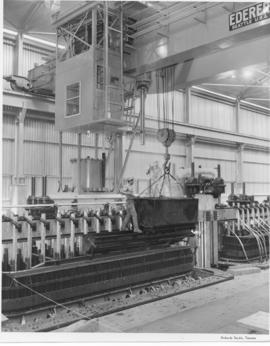

Publicity for Permanente News and Times Industrial Page, Permanente Metals, Bill Gorman. Two workmen move alumina into the reduction pots before closing the corrugated cover. Permanente produced more aluminum at this time than was produced by the entire industry in 1937, the third largest producer of aluminum in the nation. The average age of their employees was 35 years. The daily uses of aluminum were multiplying as manufacturers became acquainted with its lightness, strength, corrosion resistance, formability and appearance. (T.Times, 2/25/1949, p.36)

Permanente Metals Corp. (Tacoma)--Employees; Aluminum industry--Tacoma--1940-1950; Laborers--Tacoma--1940-1950;