- Item

- 1954-03-02

Part of Richards Studio Photographs

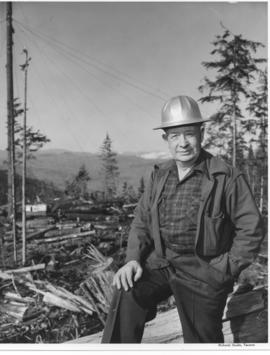

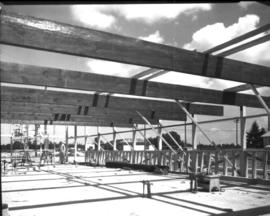

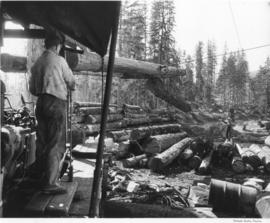

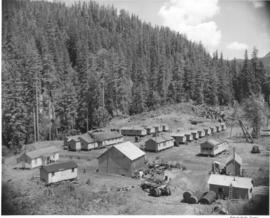

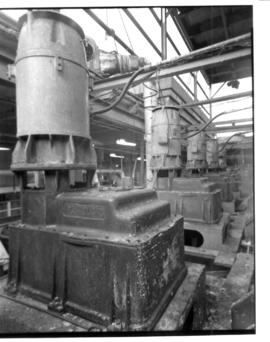

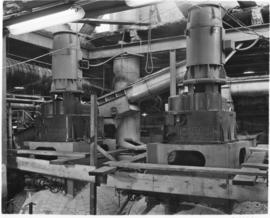

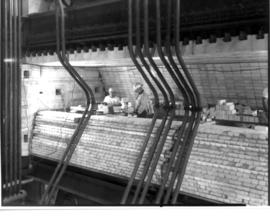

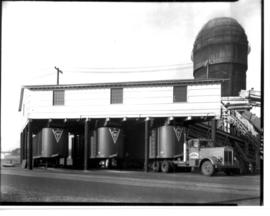

United States Plywood Corp.'s logging operation at Kosmos, Wa., eight miles southeast of Morton in south central Lewis County. A tall timber is circled by ropes and pulleys. A piece of large hoisting machinery can be seen. The ropes possibly helped bring down the trees down safely when the timber was cut.

Plywood; Lumber industry--Kosmos--1950-1960; United States Plywood Corp. (Seattle);