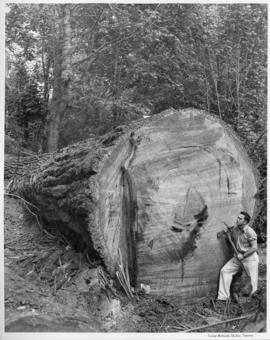

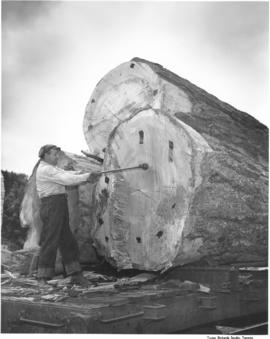

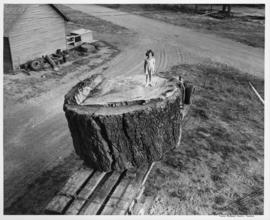

On July 30, 1946 seven children including Shirley Maras (now Walcott) (far left), Kenny Schumaker (third from left), Sharon Maras (now Gregg) (standing at top) and Marilyn Maras (now Cade)(far right) were photographed with a huge tree section that was cut from an old-growth Douglas fir that had been felled by loggers working for the Davis and Maras Company. The tree section which weighed 18,567 pounds and was over 13 feet in diameter was on its way to the Northwest Door Company in Tacoma owned by Herman E. Tenzler. Once there a gigantic slice was cut from it and put on display outside the Northwest Door entrance. Some years later the display slice of Douglas fir was moved to the Tenzler Library in Lakewood. (TNT 8/21/1946, pg. 1) (names supplied by Anthony "Spike" Maras) TPL-8386

Lumber industry--Tacoma--1940-1950; Children playing outdoors--Tacoma--1940-1950; Logs; Northwest Door Co., Inc. (Tacoma); Tree stumps--Tacoma--1940-1950; Schumaker, Kenny; Maras, Shirley; Maras, Marilyn; Maras, Sharon;