- Item

- 1946-08-02

Part of Richards Studio Photographs

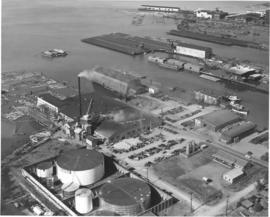

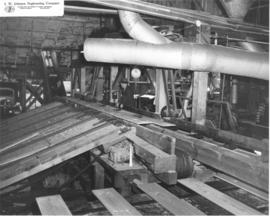

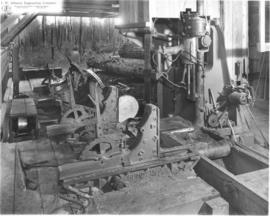

St. Paul & Tacoma Lumber Company. Several railroad cars loaded with logs are standing in the yard at the St. Paul & Tacoma Lumber Company. Large off-highway trucks, too large for state highways, brought logs down from forests to reload centers where logs were shipped to mills by railroad cars or on smaller trucks. This site of St. Paul & Tacoma Lumber was used as a large pulp mill.

Lumber industry--Tacoma--1940-1950; St. Paul & Tacoma Lumber Co. (Tacoma);