- Item

- 1955-02-14

Part of Richards Studio Photographs

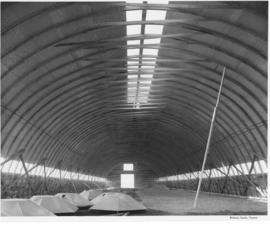

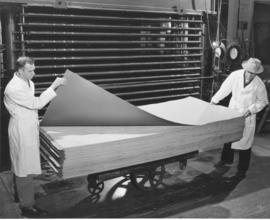

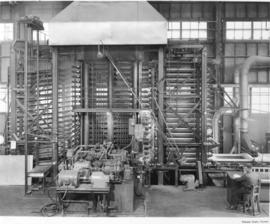

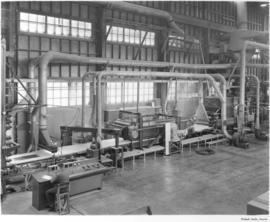

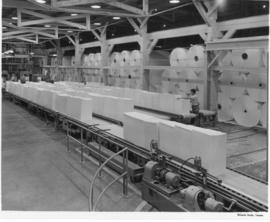

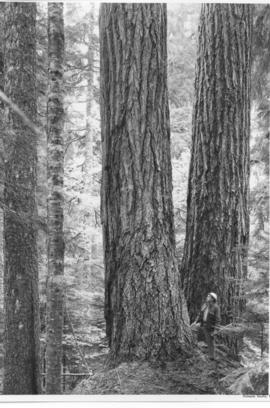

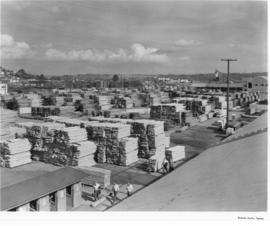

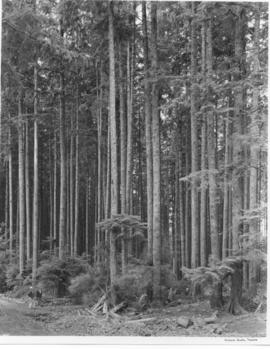

Presentation of award to the president of U.S. Plywood, Tony Antoville (on right.) Photograph ordered by the DFPA. United States Plywood Corp. was one of the first companies to build after the industry was decontrolled. It opened a 36 million foot capacity plant at Mapleton, Oregon in 1948. By 1955, the firm controlled four plants with a total capacity of 342 million feet annually.

Plywood; Lumber industry--Seattle--1950-1960; United States Plywood Corp. (Seattle); Antoville, Tony;