- Item

- 1949-08-08

Part of Richards Studio Photographs

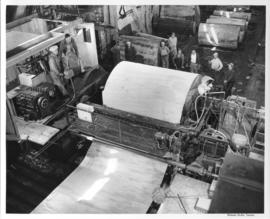

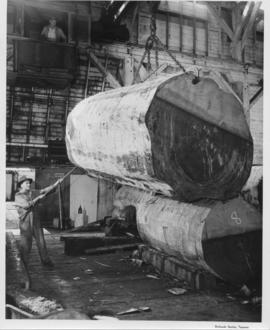

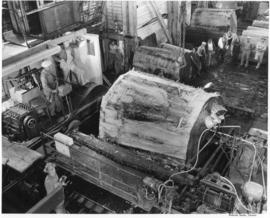

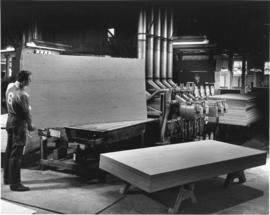

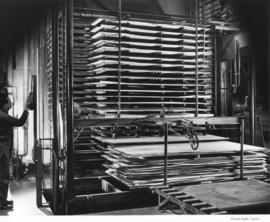

Forests throughout Washington helped maintain the the paper production in the Tacoma plant. View of the St. Regis Paper Company's crew at Camp #2, located in Mineral, Washington; Matt Zoffel is logging superintendent for operations at the camp where the crew is harvesting giant Douglas Fir trees. TPL-6319

Loggers--Mineral--1940-1950; Paper industry--Tacoma--1940-1950; Lumber industry--Tacoma--1940-1950; Logs; Firs; Forests--Mineral; Cutover lands--Mineral--1940-1950; Woodcutting--Mineral; St. Regis Paper Co. (Tacoma)--1940-1950;