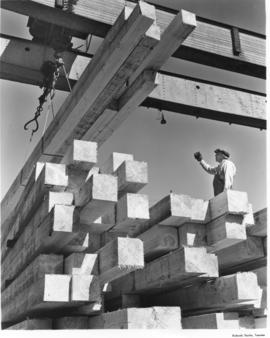

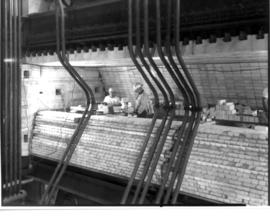

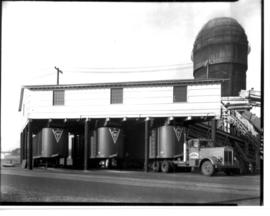

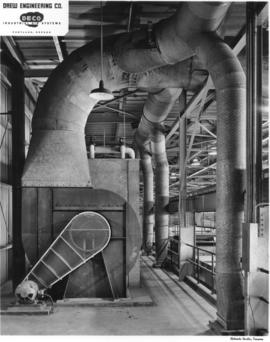

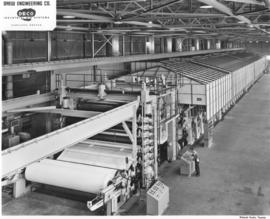

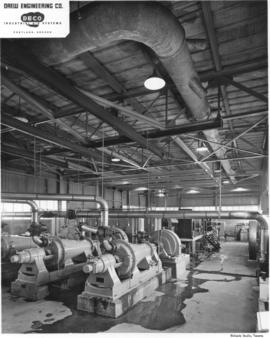

The exterior of one of the buildings at the Weyerhaeuser pulp mill at Longview, Washington, showing vents for the air system installed by Drew Engineering Company, Portland, Oregon. Longview was Weyerhaeuser's largest and most diversitied millsite in 1952. The site contained a plywood plant with a capacity of 6 million square feet of 3/8-inch plywood per month and a bark products plant where Silvacon was produced for use as plywood glue, rubber products, oil well drilling, mastic flooring and in plastics. The location also maintained a pulp log barker, chippers for the pulp plants, and a sulphate pulp mill with its 225 tons of bleached Kraft pulp each day. The wood fiber plant processed Silvacel for cold storage insulation and oil well drilling, and Silvawool for home and building insulation. The plant also maintained a development department and the fabrication department which turned out Monocord trusses and laminated beams. (Weyerhaeuser Magazine, June 1952)

Weyerhaeuser Timber Co. (Longview); Mills--Longview; Lumber industry--Longview; Drew Engineering Co. (Portland);