- Item

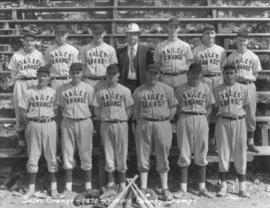

- 1938-08-26

Part of Richards Studio Photographs

Sales Grange Baseball Team, 1938 Pierce County Champions. Saxton Lumber Company baseball team c/o Paul Froman. 12 men in uniform, man center back in suit, equipment in front; posed on wooden bleacher steps.

Saxton Lumber Co. (Tacoma)--Employees; Lumber industry--Tacoma--1930-1940; Baseball players--Tacoma--1930-1940;