- Item

- 1948-02-12

Part of Richards Studio Photographs

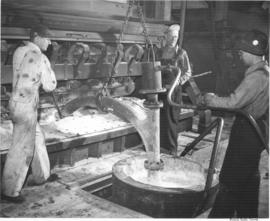

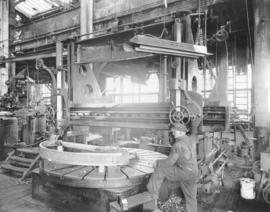

Girls from Catholic College visiting Permanente plant, Bill Gorman. Students watch while molten alumina is siphoned from a reduction cell into a large crucible at the Permanente plant. Tacoma Catholic College had purchased the former Weyerhaeuser mansion, Haddaway Hall at 4301 No. Stevens St., and converted it into a Junior College for Women.

Permanente Metals Corp. (Tacoma); Aluminum industry--Tacoma--1940-1950; Foundries--Tacoma--1940-1950; Laborers--Tacoma--1940-1950; Students--Tacoma--1940-1950;