- Item

- 1949-01-08

Part of Richards Studio Photographs

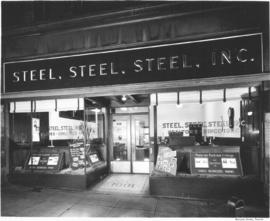

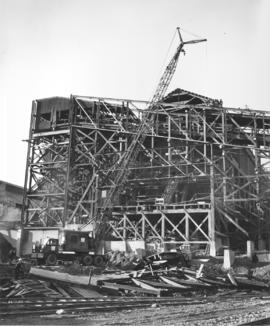

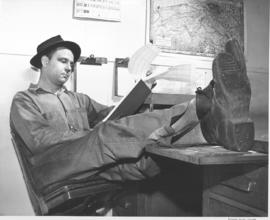

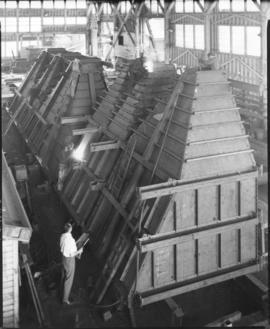

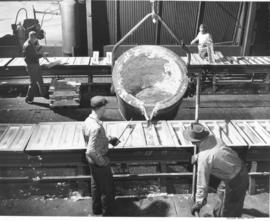

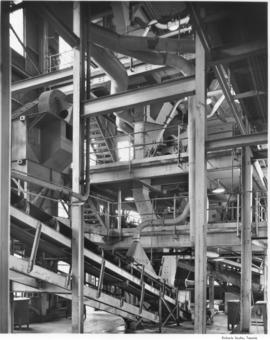

Rainier Steel Company had just started operating in the steel industry in Tacoma, this company was the only one of its type in this regional area. Rainier would be producing and selling their steel to automobile companies in Detroit, Michigan. Eugene Cunningham was the President of Rainier Steel Corporation, the plant facilities were located at 2201 Lincoln Avenue in Tacoma's tideflats area, between Blair Waterway and Hylebos Waterway.

Steel industry--Tacoma; Steel; Industrial facilities--Tacoma; Foundries--Tacoma; Aerial photographs; Aerial views; Rainier Steel Corp. (Tacoma);