- Item

- 1912

Part of Richards Studio Photographs

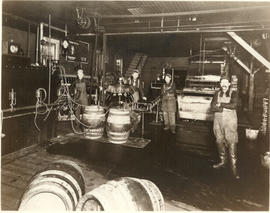

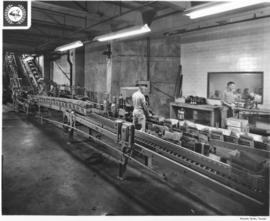

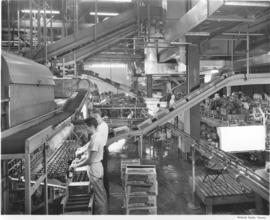

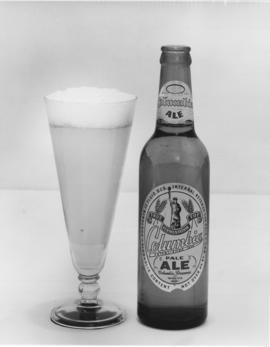

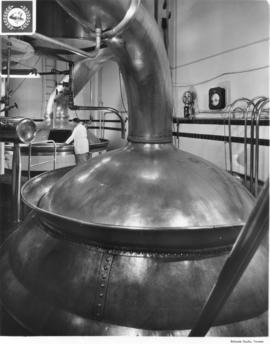

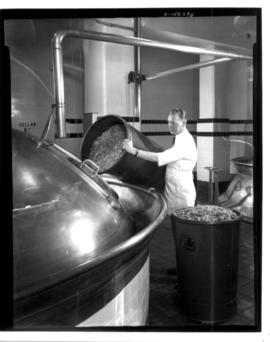

ca. 1912. The name painted on the side of the brewery is the Columbia Brewing Company. The building was built in 1900 when the brewery was established. Like most early breweries this building was tall and took advantage of gravity in moving materials through the brewing process. Grain storage and milling was often located high in a brewery on the 3rd or 4th floor. The copper brew kettle was commonly located beneath the mash tun at ground level. Copies of old prints ordered by Columbia Breweries in 1951. (Brewed in the Pacific Northwest, Gary and Gloria Meier)

Brewing industry--Tacoma--1910-1920; Columbia Brewing Co. (Tacoma);