- Item

- 1952-01-28

Part of Richards Studio Photographs

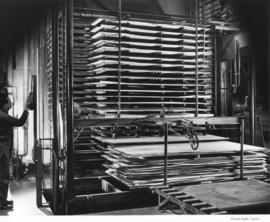

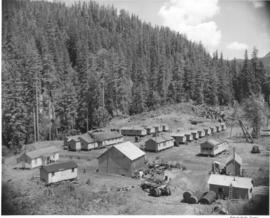

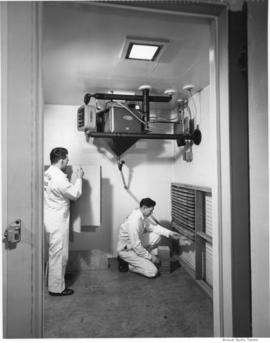

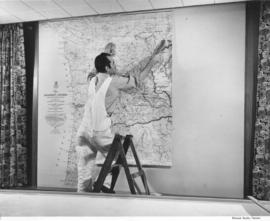

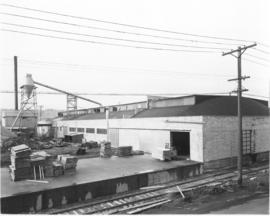

Rayonier, Inc., lumber company, skit at conference held at Winthrop Hotel. Eight men in front of factory mural. Rayonier manufactured cellulose products for rayon and acetate staple fibers in fabrics. However, the fastest growth occured in tire cord, cellophone and other uses entirely apart from textiles. Rayonier had been diversifying over a period of years hoping to be less affected by fluctuations of demand in the textile markets. Note: Lines in print due to diacetate film deterioration. One of several thousand images preserved through copying by Tacoma library. (Rayonier, Inc., 1951 Annual Report)

Rayonier, Inc. (Tacoma); Lumber industry--Tacoma--1950-1960; Hotel Winthrop (Tacoma);