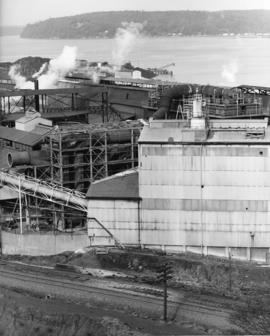

Atlas Foundry, crane for Broderick & Bascomb, wire rope. A crane is being used to set a pole alongside a railroad track. Atlas Foundry and Machine Company was engaged at this time in work for plywood, pulp and paper, railroad and other industries. The company reports work was coming in from all over the west coast. This photograph was used in a newspaper article, Tacoma News Tribune, February 14, 1950, about the poles manufactured by Cascade Pole Company, located on Port of Tacoma Road, that were used for telephone and telegraph poles throughout the world. (T.Times, 8/28/1946, p.5)

Atlas Foundry & Machine Co. (Tacoma); Hoisting machinery; Railroad cars--Tacoma--1940-1950;