- Item

- 1949-01-21

Part of Richards Studio Photographs

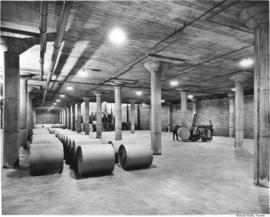

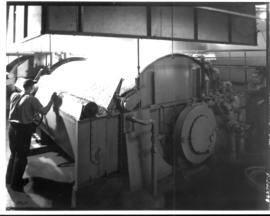

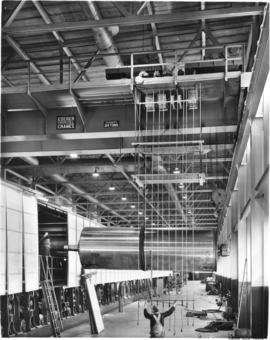

Two workers are pictured unloading a roll of Kraft paper to join others already stored in St. Regis' paper storage room. St. Regis had began producing paper in January of 1949 as it used the most modern equipment available at the time to convert liquid pulp into heavy multiwall Kraft paper. The plant was able to produce about 240 tons of multiwall bag paper per day.

Paper industry--Tacoma--1940-1950; Paper; Hoisting machinery; Machinery; Equipment; Industrial facilities--Tacoma; St. Regis Paper Co. (Tacoma)--1940-1950;