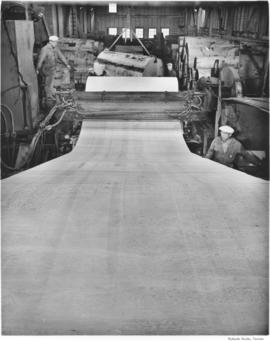

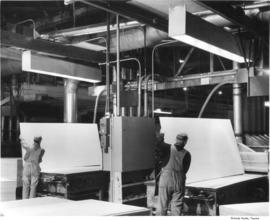

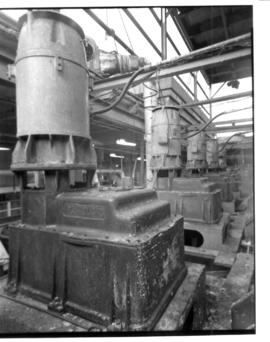

On February 5, 1948, thirty-five students from a special merchandising course at the University of Washington received first-hand knowledge of plywood, door and millwork production at several Tacoma plants. At the Wheeler Osgood plant, 1216 Saint Paul Ave., students watched William Holecheck operate a machine which clamped together the various plywood and wood parts of a 3-panel door. They also visited Coast Sash and Door. Photograph ordered by Mr. McCallum. (T.Times, 2/6/1948, p.15 and TNT, 2/6/1948, p.17)

Wheeler, Osgood Co. (Tacoma); Lumber industry--Tacoma--1940-1950; Factories--Tacoma--1940-1950; Doors & doorways--Tacoma; Students--Tacoma--1940-1950; Teaching--Tacoma;