- Item

- 1938-08-23

Part of Richards Studio Photographs

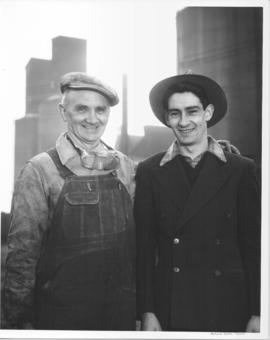

Star Iron & Steel Company bridge fabricated in five days for Whidbey Island-Mukilteo ferry landing. On August 23, 1938, the Cooney Transfer & Storage Company transported the 30,000 pound, 64 foot-long steel bridge on a Becholdt trailer. The original wooden ferry landing structure was ripped out by the ferry a week ago. Within five days, the plans were drawn for the steel replacement, the steel was fabricated and two coats of paint were applied. (T. Times, 8/23/1938, p.3).

Star Iron & Steel Co. (Tacoma); Cooney Transfer & Storage Co. (Tacoma); Bridges--Whidbey Island; Trailers; Shipping--Tacoma--1930-1940;