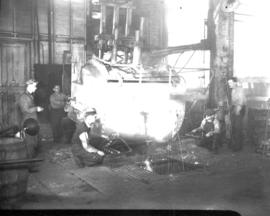

Permanente. Two men are having fun with a load of alumina, a fine white powder that is refined from alumium-bearing ore, bauxite. Bauxite was mined in South America, refined, using the Bayer process, in Baton Bouge and shipped by rail to the Pacific Northwest where it was converted into primary aluminum. Four pounds of bauxite were required to obtain two pounds of alumina shich yields one pound of aluminum. As of September 1948 nearly 500 boxcar loads of alumina per month were brought to Tacoma and Mead aluminum reduction plants, thereby becoming one of the largest users of boxcars in the Northwest.(Permanente Metals Corporation 1947-1948 Annual Report; T.Times, 9/6/1948, p.12)

Permanente Metals Corp. (Tacoma)--Employees; Aluminum industry--Tacoma--1940-1950; Aluminum; Minerals--Tacoma; Laborers--Tacoma--1940-1950;