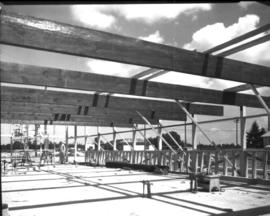

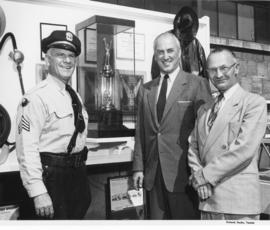

Members of the staff of Heidelberg Brewing Co. and of Bona Fide Builders construction company inspect the scale model for the new 3/4 million dollar "Brew House" to be added to the brewing plant on So. C St. The construction of the four story storage cellar has been contracted with Bona Fide Builders Inc., a Tacoma construction company. The basic contract is for $350,000 for the construction of a reinforced concrete building to house the cellars. The building will cover an area 55 x 140 feet on So. C. The tank and refrigeration contracts bring the cost to $800,000. The glass lined tanks have a capacity of over 1,000 barrels each. The production of the new plant is estimated to be 750,000 barrels annually. Pictured, left to right, are Anders W. Erickson, Brewmaster, T.L. McCormick of the architectural designers, Michael M. Kneip, Assistant Brewmaster, Joseph Wohleb, Brewery architect, W. Boyd Dickson Jr., President of Bona Fide Builders, Hollis Kerr, Heidelberg construction superintendent, Nick Ockfen, Bona Fide superintendent of construction, L. Paul Marten, engineer for the brewing co., A.L. Waterbury, Chief Engineer of the brewing co. and Bailey H. Nieder, technical assistant and manager of engineering department of the brewing co. (TNT 7/16/1953, pg. C-13)

Brewing industry--Tacoma--1950-1960; Bona Fide Builders Inc. (Tacoma); Erickson, Anders W.; Kneip, Michael M.; Wohleb, Joseph; Dickson, W. Boyd; Kerr, Hollis; Waterbury, A.L.; Heidelberg Brewing Co. (Tacoma)--1950-1960;