- Item

- 1973

Part of Richards Studio Photographs

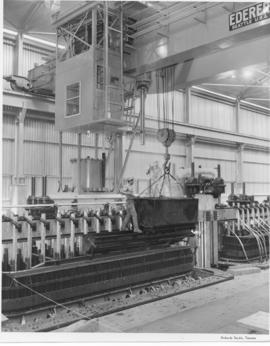

ca. 1973. Standing over a hundred feet tall is this unidentified supporting structure at Kaiser Aluminum's Tideflats plant. Its size is apparent compared to the man standing at the foot of one of the supports. Even the truck nearby appears miniscule. Photograph ordered on December 19, 1973, by Puget Sound Fabricators, Seattle.

Kaiser Aluminum & Chemical Corp. (Tacoma); Aluminum industry--Tacoma--1970-1980;