- Item

- 1974-06-10

Part of Richards Studio Photographs

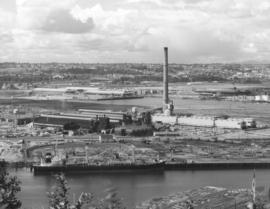

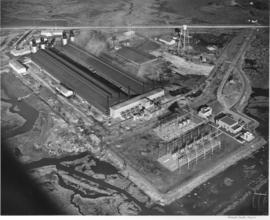

Kaiser Aluminum plant. This aerial view of the Kaiser Aluminum plant was taken on June 10, 1974. The plant was located in Tacoma's tideflats at 3400 Taylor Way. The wisps of smoke emerging from the plant's 500-foot stack appear to blend into the heavy cloud formation. Color photograph ordered by Kaiser Aluminum.

Aerial photographs; Kaiser Aluminum & Chemical Corp. (Tacoma); Industrial facilities--Tacoma--1970-1980; Aluminum industry--Tacoma--1970-1980;