- Item

- 1958-08-05

Part of Richards Studio Photographs

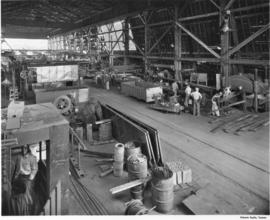

An employee of Ace Furnace & Steel Co. leans one arm against a massive steel jet propulsion fuel storage tank on company property on August 5, 1958. He appears diminutive when contrasted with the 10.6 foot diameter tank. The gas tank measures 77.5 feet in length. Ace Furnace produced steel storage tanks for oil, gasoline and water, stacks, marquees, canopies, steel heating and ventilation systems, boilers, furnaces, and marine sheet metal. The company's major output now are tanks of all sizes, approximately 400-800 tanks per month. The huge tanks pictured above were just built for McChord Air Force Base. It is estimated that these were the largest shop fabricated steel tanks ever built in Tacoma. The Northern Pacific cars in the background would make transportation of these heavy steel products easier and more efficient. Photograph ordered by Ace Furnace & Steel Co. (TNT 9-1-58, C-7)

Ace Furnace & Steel Co. (Tacoma); Steel industry--Tacoma; Storage tanks--Tacoma; Railroad freight cars--Tacoma--1950-1960;