- Item

- 1947-10-31

Part of Richards Studio Photographs

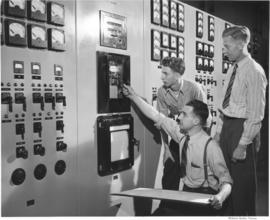

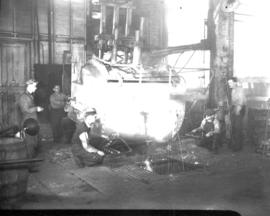

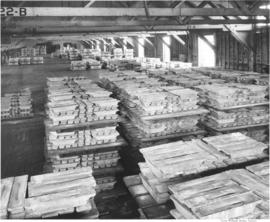

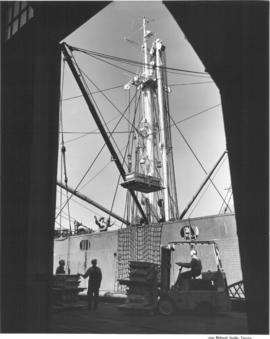

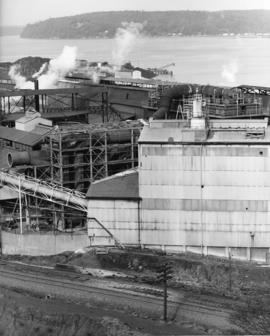

View of new pot line at the Tacoma reduction plant of the Permanente Metals Corp. It is the first reduction plant in the world to be thoroughly equipped with a scrubber system. This equipment is able to automatically wash away the fumes that are given off in the reduction process. The system consists of individual collectors connected to each pot and several washing stations. Permanente staff can be seen in the center area of the reduction plant.

Aluminum industry--Tacoma--1940-1950; Industrial facilities--Tacoma; Equipment; Machinery; Control rooms--Tacoma; Permanente Metals Corp. (Tacoma);