- Item

- 1935-01

Part of Richards Studio Photographs

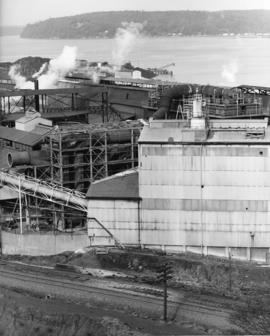

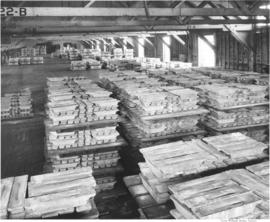

American Smelting and Refining Company (ASARCO), Tacoma. Worker directing activity of a large crane constructed over railroad tracks at the edge of Commencement Bay. Ships were loaded and unloaded at this point. The mechanical crane could carry 5 tons of ore on each dip into the hold. For J. Gius, reporter.

American Smelting & Refining Co. (Tacoma); Smelters--Tacoma--1930-1940; Copper industry--Tacoma--1930-1940; Industrial facilities--Tacoma;