- Item

- 1937-01

Part of Richards Studio Photographs

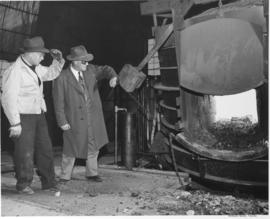

In January of 1937, a team of workmen at the Atlas Foundry, 3012 So. Wilkeson St. were photographed pouring molten metal into a small mold. In 1937 the Atlas Foundry employed 97 skilled workmen, and was the largest foundry on the Pacific Coast. Their three story pattern building housed over 50,000 wooden patterns, from which they could make castings varying in size from a 2-ounce bronze boat fitting to a 16-ton cast iron slag pot. Founded in 1899, the Atlas Foundry is now Atlas Casting & Technology. (TDL 3/28/1937)

Atlas Foundry & Machine Co. (Tacoma); Foundries--Tacoma--1930-1940; Steel industry--Tacoma--1930-1940;