- Item

- 1948-12-03

Part of Richards Studio Photographs

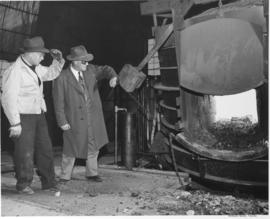

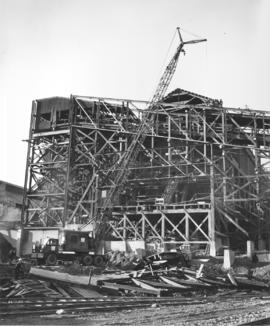

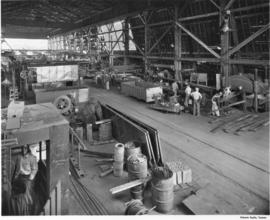

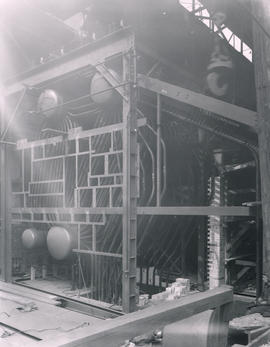

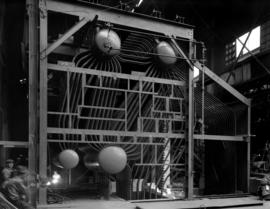

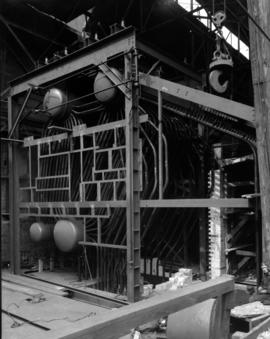

When the Rainier Steel Corporation began operations at 2201 Lincoln Avenue, on Tacoma's tideflats, in December of 1948 it became Tacoma's only steel plant at that time. Here an unidentified employee of Rainier Steel, in special safety glasses, monitors work being done in the facility. Eugene Cunningham, president and general manager, started the Rainier Steel Corporation because of the acute steel shortage after WWII. Rainier Steel used scrap iron as its raw material and their furnaces melted the iron and produced steel. The company planned to employ fifty people once they reached full operating capacity which was 100 tons daily with the present equipment. The steel was sent to Detroit for use in the automotive industry. (T. Times, 12/13/48, p. 5-article).

Foundries--Tacoma; Founding--Tacoma; Iron & steel workers--Tacoma; Steel; Steel industry--Tacoma; Hoisting machinery; Industrial facilities--Tacoma; Furnaces--Tacoma; Rainier Steel Corp. (Tacoma);